POWERCHOCK® HYBRID secures all types of vehicles at the same loading dock:

- Semi-trailers

- Carrier trucks

- Container trucks

- Delivery vans

Download the brochure to discover all its great features.

POWERCHOCK® HYBRID secures all types of vehicles at the same loading dock:

Download the brochure to discover all its great features.

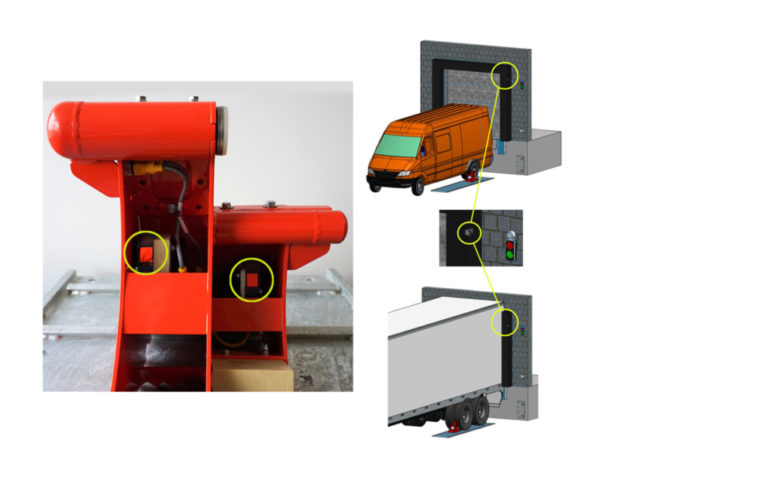

■ Dual-height, high-tensile steel wheel chock, installed on an ergonomic articulated arm or trolley.

■ Two sections (totalling 3,60m) of hot-dip, galvanized steel, ground-fixed restraining plate, in the dock bay area. Additional sections of restraining plate optional.

■ The wheel chock has a 27 cm section for delivery vans and a 40 cm section for heavy trucks. A sensor detects the type of vehicle and selects the appropriate section to be positioned.

Control system consists of up to 6 sensors linked to an audiovisual communication system:

■ 2 wheel sensors inside chock to confirm proper wheel chock placement

■ 1 dock sensor to confirm door closure

■ 1 arm sensor to confirm return of arm to resting position on the wall

■ 1 vehicle sensor to identify vehicle height (semi–trailer, delivery vans, container truck, etc.)

■ 1 optional leveler sensor to confirm leveler shutoff

POWERCHOCK® control box is a powerful communication system that is easy to understand for all warehouse workers.

It is interfaced with the door and the leveler controls and has a programmable control mode with self-diagnostic function of the electrical components, to integrate all the equipment of the platform.

■ Our POWERCHOCK® systems are designed to cope with extreme winter conditions.

■ To deal with repeated snowplowing, an optional 3 directional snow plate may be anchored to the ground.

■ An optional 3-directional heating restraining plate may also be installed.