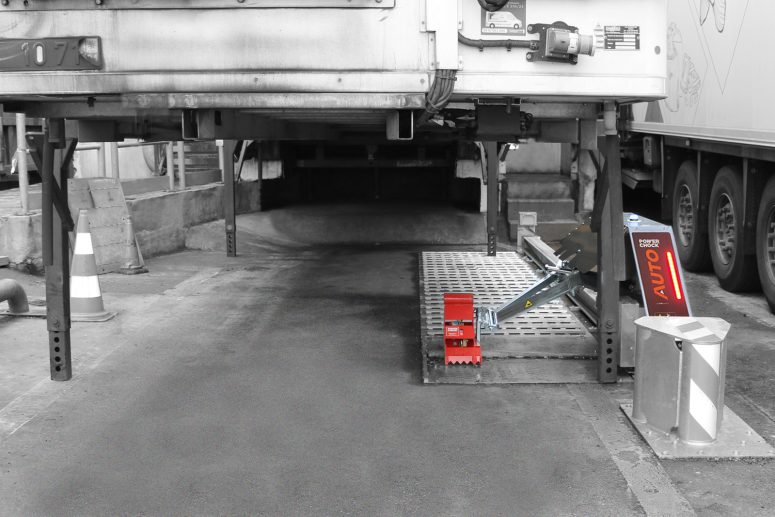

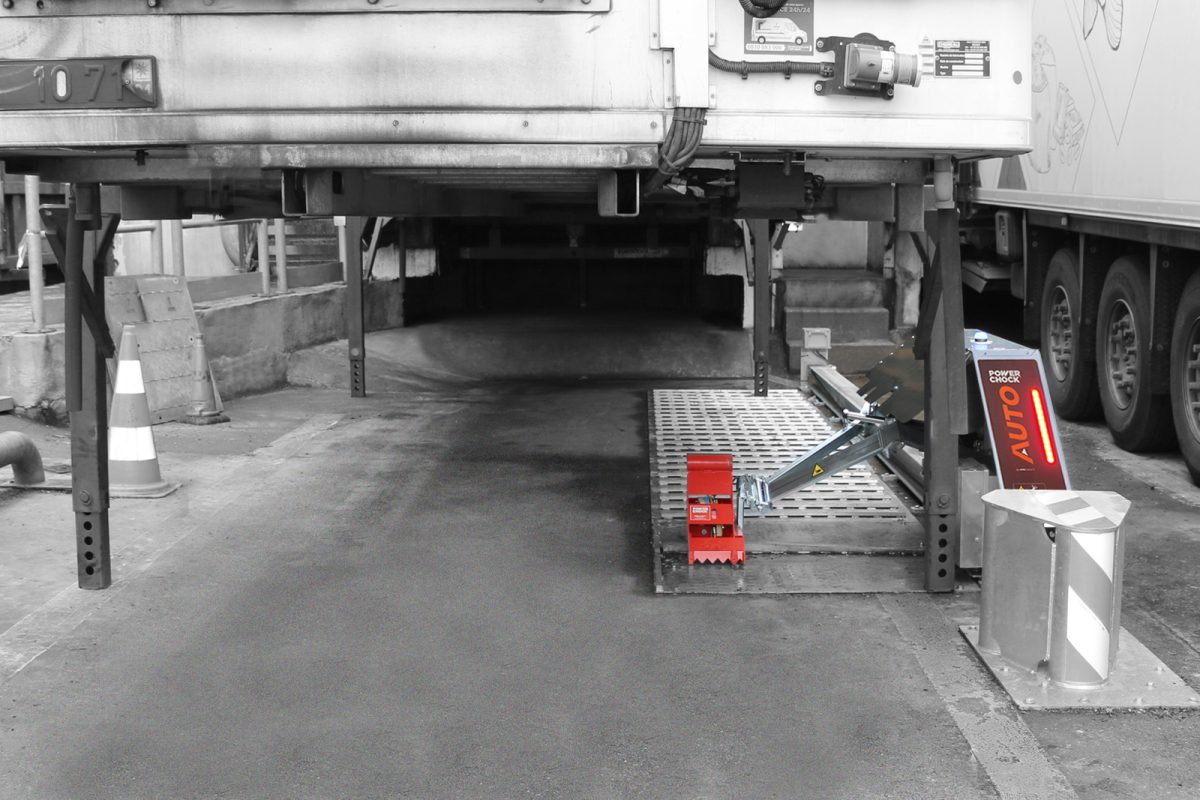

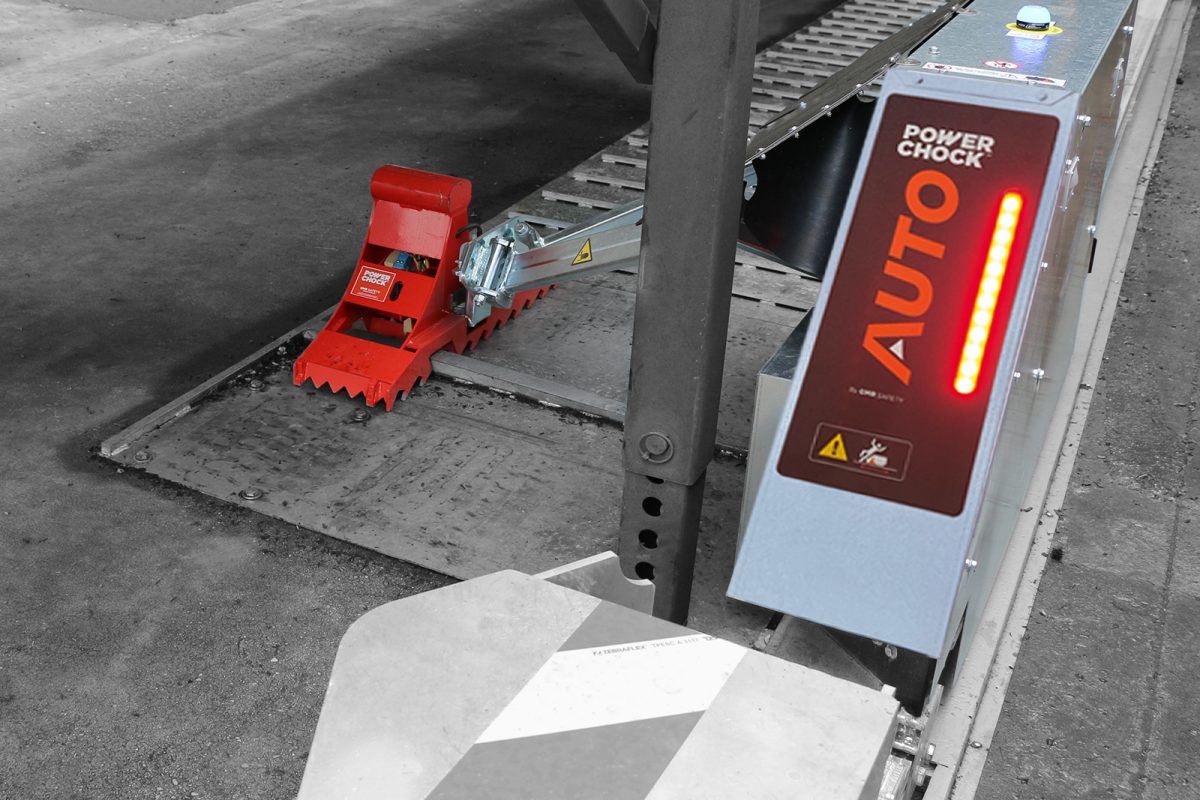

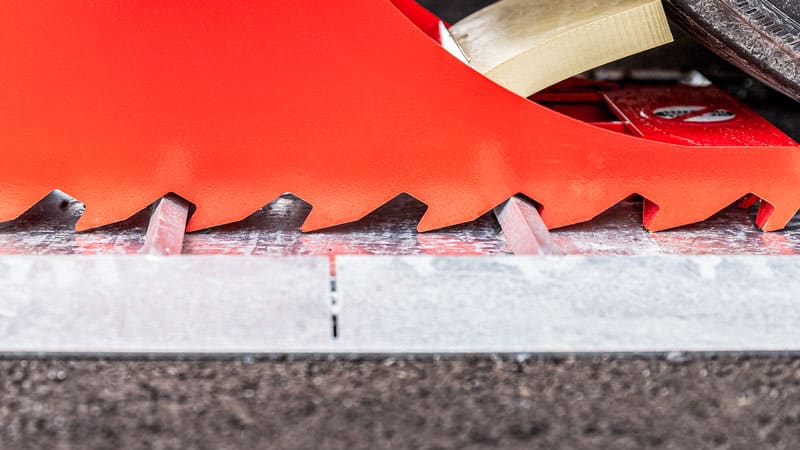

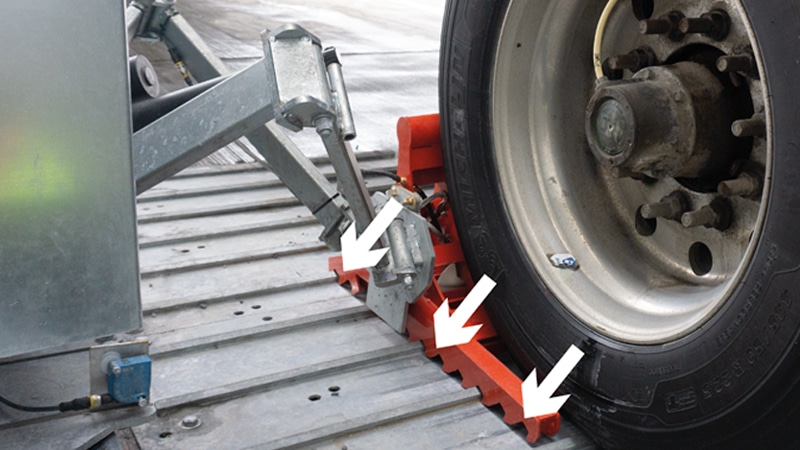

POWERCHOCK® AUTO is our new automatic vehicle restraint. Designed to meet new industry standards for automation, it offers enhanced safety by eliminating the need for the trailer driver to be involved in securing the loading dock.

Compatible with all vehicles, this model provides universal, high-performance securing, making it the optimal choice for effective trailer restraint.